In today’s world of modern technology, managing inventory is a boom as well as overhead at the same time. With just-in-time inventory services and online shopping, many business models are rethinking of ways to reduce the inventory management limitations and moving to more on-the-spot solutions for stock maintenance.

Inventory management can have different perception based on the kind of business solutions, but inventory management system acts as a lifeline for majority retail businesses. Stock maintenance can be quite intimidating for growing business venture, as naming and tagging each and every material seems to be a huge job. But, implementing an automated online Inventory management software can resolve all such trivial issues of stock maintenance and help you to maintain a perfect balance of demand supply chain.

Read More – Online Inventory Tracking Software

Let’s understand what is inventory management and how can an inventory management solution help to regularise it.

Inventory Management is a process of tracking each and every item of stock as it is brought into or as it leaves the warehouse. This helps to monitor the inventory trends in our warehouses.

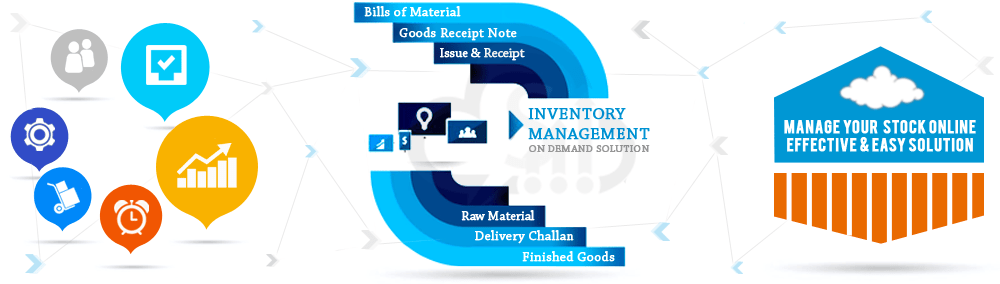

As discussed, managing every inventory item manually through spreadsheets and documents can be hectic and unproductive. Hence, an Inventory management system a.k.a inventory control system provides an automated system for tracking inventory levels, orders, sales and deliveries for your business. These online inventory management solutions are also used in the manufacturing industry to create quick work orders, bill of materials, challans and other sales receipts and documents.

These inventory management solutions provide a systematic approach towards balancing “out of stock” and overstock situation in warehouses. There are many functionalities which can be leveraged from an inventory control software to control and manage our stocks, some of them are listed below:

Advantages of an Inventory Management Software

1. Centralized Data Management:

An efficient inventory control system, such as SalesBabuCRM, provides a cloud-based centralized database for comprehensive information storage encompassing every detail related to stocks. From raw materials accumulation to final products manufacturers, vendors, purchase and return receipts, and other pertinent details, the system manages an online database available in real time by the entire stakeholders in the sales and marketing team members.

Manually monitoring inventory movements across several business models can be inefficient and prone to human mistakes and rework. The inventory management system delivers a consolidated approach to administer inventory across all sales channels.

Read More – SalesBabu Inventory Management Software for Inventory Management for SME

2. Tracking Through Receipts and Challans:

Receipts and challans deliver an important role in monitoring customer deliveries, product quantities delivered, customer acknowledgments, and further management processes. Such documents synchronize detailings between customers and vendors, delivering clarity on the quantity and timeline of product deliveries. Challans are beneficial for tracking every stock exchange within and outside the organization.

Furthermore, Goods Receipt Notes (GRN) contribute to managing the integrity and consistency of product delivery, promoting long-term relationships with customers.

3. Analysis and Metrics:

In inventory control, the generation of evaluation and metrics is pivotal for understanding customer shopping trends, figuring popular products, maintaining outdated stocks, and available entire stock values. These metrics cater to make productive statistics for stock maintenance and upkeep, allowing businesses to predict and plan in advance for improved productivity and revenue generation.

4. On time delivery tracking

On time delivery is very important in today’s world of internet shopping and versatile shopping trends. Many small scale businesses and startups lose their customer due to mismanaged and delayed delivery process. With every lost customer, not only chances of winning them back diminishes but also increases the risk of losing many more client due to social media and web chat feedback sharing.

An efficient inventory control tool helps to maintain every detail on customer delivery in a centralised location which can be accessed and referred to by every sales and marketing team. With these details in hand, product delivery can be planned well in advance to avoid any mismanagement and delay in final product shipment.

5. Demand forecasting

Demand forecasting is the buzzword in today’s world of economic business management. These demand and supply forecasting helps to plan what and when to order, so that we can allocate resources wisely. With these forecasted values, we can understand which product is selling more and which products are not needed in the warehouses and reordering should be avoided. At the same time, demand forecasting helps to calculate the amount of products which needs to be kept for stock safety and backup to maintain a smooth balance between demand and supply chain.

6. Cost Saving

With the assistance of Inventory management software, you can avoid dead stocks and overstock situations. Inefficient management of inventory may lead to revenue loss and over-spending of money. By streamlining the management you can not only reduce the costs, but you can also earn profit by saving the further costs. The software helps to get the history product by which you can refill the stock and manage the inventory.

7. Reducing the Inaccuracies

Inventory and stock management consist of an array of internal management processes. When all the tasks are done manually there are chances for the inaccuracies like data duplicity. But once when you adopt the inventory management software, it will automatically record the data and track the processes leaving no errors.

8. Happy customers

Decent stock management keeps the clients returning for more. Good stock management will lead you to what you are aiming for and repeat the clients. You should be able to meet the requirements of customers and satisfy them.

9. No more manual work

When you manually work there are cases that you make more mistakes. You don’t need to make those calculations yourself. Without the inventory management software, a lot of hours will be wasted. The team will record what items you have used for the transaction. Inventory management software will do all these works efficiently.

10. Data Security

In the inventory management software, you can restrict the users according to your requirement. By restricting the users and giving rights to them will prevent them from making mistakes. Another benefit is it provides security at all levels. Every user is restrained because there will be no chance of data loss or leakage of data. The worker can write the data of the product and the manager will approve if the data is correct and in proper order.

With these benefits of inventory management solutions, we can create an efficient platform for a balanced sales cycle.

There are many inventory management users who feel that we can improve our business performance better by continuously improvising on our inventory control tool. Let’s understand how can we boost up our inventory management systems.

Read More – Efficient Inventory Management System

Ways to boost your inventory management system

1. Streamlined Inventory management

With online marketing and world wide customers, we can only think of solutions which can be used globally providing real time access to product delivery and process management. With cloud based inventory system, we can boost our business revenue by managing our products, vendors, delivery status and various other details on stock maintenance.

Many companies get badly hit due to mismanaged teamwork and unorganised manufacturing, procurement and delivery team. Also, these mismanaged team work may also delay customer deliveries which can cost a huge hole in the business revenue process. With an efficient stock control system, we can not only manage our products and raw material but also provide a collaborated system of streamlined process management.

2. Easily Maintain Stock Levels

Automating your inventory management system is very important to improve your stock maintenance process. The more automated the stock control system is, the more time the team members get to create more productive sales and contribute to improve business revenue. At the same time, creating an automated system of stock count and safety stocks help to balance the demand and supply chain, improve overall business profit and customer satisfaction rate.

3. Reduce the Costs of Storage and Insurance

Warehouse inventory management and product insurance are the major cost investment areas of inventory holdings. If we have a big warehouse to upkeep, we need to spend on rent, manpower, security, backup and many other resources which adds on to the overall business cost. Also, if we need to ensure our products from theft and natural damages, we need to spend some more extra money for buying insurance policies for our stocks.

With the help of a good material management system, we can predict a better amount of stocks which are needed for our business. Certainly, as we grow we need also keep scalability cost and future business requirement into check with these stock control tools to avoid any last minute orders, transport and other charges which can add to more overheads on inventory storage.

An efficient cloud based inventory software, will keep most of the data over the cloud which will significantly reduce the human resource, rework and maintenance cost as low and possible and help to streamline your inventory planning, increase your business profits, and allow you to invest wisely on business expansion.

Read More – Reduce Operational Cost With Inventory Management System

4. Reordering Stock

As we mentioned earlier, a good inventory management system provides various facilities of metrics and analysis which not only helps us to understand our current product requirement but also helps in making more informed decisions on the future stock requirement for balancing our sales supply chain.

Reordering can cost a lot of money due to the repetition of procurement cost in the business. With an efficient inventory control system, we can manage our reordering process by looking at our demand history and automatically reorder our best sellers and minimize any obsolete and non sellers. This will help us to continue to supply our best products to the customer and save on extra spending on non sellers.

5. Remove manual processes and error management

Error handling and reworks are some of the major cost incurring activities in mismanaged inventory management systems. With employees manually updating sheets and documenting orders, the chances of errors and mismanagement increases, costing a lot of business loss to companies. With centralized databases and automated data management of products, vendors, challans, acknowledgement receipts etc, every employee will be more efficient in using his productive time in doing more productive work for better revenue generation.

With constant automation and intelligent software implementation, we can not only save time for the employees but also improves the productivity of the team by doing more profit oriented jobs and responsibilities instead of completely menial jobs.

A good inventory management solution should continuously work towards reducing manual processes and creating a more productive environment for employees.

Conclusion

We as a business venture should understand that as we expand, we should have tools which should not only stay with us but also grow with our business growth and continue to support our business revenue generation process. With new technologies and economic market changes, we need to keep our Inventory management software at the core of your plan to have a consistent and productive solution for all our stock control requirements.